LFG Tech provides custom built blower and compressor packages for direct gas sales projects. As with the engine fuel gas boosters, proper handling of liquids is critical to the over all success of the package.

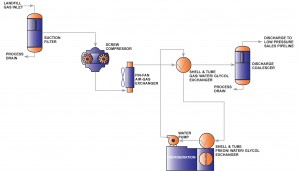

The following pictures and simple diagram provides the typical operational logic for a typical direct gas sales package:

Click here to request additional flare information or request a quote.

Typical Low Pressure (5-36 PSIG) Direct Gas Sales Flow Diagram

Typical High Pressure (40-150 PSIG) Oil Flooded Screw Flow Diagram

Fuel Gas Booster Components to Consider:

Blower: Tuthill or Roots positive displacement blowers

Compressor: Frick, Viltor, or equivalent

Standard Murphy Control Panel: Class 1 Div II Panel

Custom PLC Control Panel: PLC Control with selection of PLC

Pressure Control Materials:

- Pneumatic pressure control with V-ball valve and controller or Variable Frequency Drive with back pressure regulator.

- All gas wetted parts 304 SS

- Fin/fan cooler tubes SS, box headers CS

- All valves CS with SS trim

- CS flanges